Update April 13, 2021

A year after this project began, we are happy to say that with a good supply of PPE and now the wonderful vaccines being administered, we do not believe we will need to reinstate this project. Thank you again to all in the community who stepped in to help when there was a need.

Update April 14, 2020

We’d like to extend our gratitude to the many volunteers in the community who so quickly stepped up to help produce the masks the UF College of Medicine’s department of anesthesiology worked with local sewists to design.

We are pausing production of the masks directed to our UF Health facilities, as we are well-stocked at this time, both with N95 masks and other general mask options.

We have been so appreciative of the outpouring of support. We know that for many, masks are a precious resource, and we want to ensure they now go to those who are most in need of them in the surrounding community. If community sewists wish to continue making the masks, they may use the designs provided below but UF Health will not be able to provide sewing kits or material or assume liability for masks made outside of the purview and supervision of UF Health. Any new masks that are made can be given to those people in the community who are most in need.

We are thankful for those who stepped up to help with this important project and will be sure to contact you again if we need assistance in the future.

It’s heartening to see that together we were able to offer solutions to meet needs that many are experiencing across the country. Our hope is that this effort will continue to benefit others and provide them with the information they can use to help their own communities.

The University of Florida Health’s department of anesthesiology has developed 2 prototypes for masks that can be produced in large quantities using materials already found in hospitals and medical facilities.

*UF has a patent pending on this FaceMask (Appl. No. 62/994,073)

Both prototypes have been fit tested. We are still refining our designs and assessing which work better for different types of faces. We will update this as we gain experience.

PROTOTYPE 1

This prototype involves a three-pleat design that hugs the face from below the eyes to below the chin.

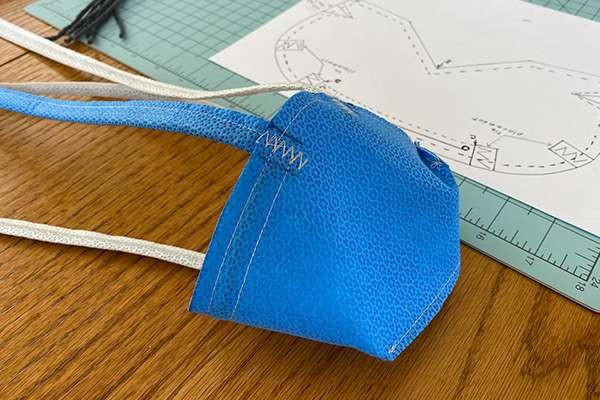

PROTOTYPE 2

This prototype involves a cone shape around the nose and the mouth. A wire is inserted so the mask will fit snugly on the nose. It has darts to snug the mask under the chin. There is no binding on this mask.

Mask Prototype 1 Instructional Video

Mask Prototype 1 Instructions

Download a pdf of these instructions.

This mask consists of two layers of HALYARD H600 medical fabric. The blue side is the right side and will face out.

The mask has passed the Respirator Fit Test. Please note that the masks will be sterilized after they are returned to the hospital.

Supplies

- Medical grade fabric (Halyard H600) supplied by hospital

- One piece of 16-gauge wire (not aluminum as it is too soft)

- 100% Acrylic yarn, size medium # 4 (used for ties)

- Cutting mat, ruler, rotary cutter if available

- Sewing machine, thread, scissors, sewing clips/paperclips, seam ripper (NOTE: please use pins sparingly to avoid holes)

- Jewelry pliers or needle nose pliers and wire cutters

Directions

- Cut two pieces of the Halyard fabric 7” × 8” (mask body) and two pieces 1” × 36” (tie/binding fabric). The blue side will be the outer side of the mask and the white side the inside of the mask. The 7″ sides will be the width across the top and the bottom of the mask. The 8-inch sides will be pleated. Three pleats will make the final mask 4″ deep.

- Layer the 2 pieces of 7″ x 8″ fabric on top of each other. Sew a 1/4″ inch seam on the 7″ sides.

- Turn the mask right side out. Finger press and clip, topstitch 1/4″ from both edges on the sides you just clipped.

- For the nose piece, cut the wire into a 6” piece. Make a small loop on each end of the wire and press flat. See image 1. The loops should be facing the same way. Insert the prepared wire into the 1/4″ seam on one of the sides you top stitched. Center the wire. This is now the TOP of the mask.

- Mark 2″ down from the TOP edge of the mask on both sides. Make three accordion-style pleats along the 8″ side as follows: Make the 3 half-inch pleats starting at the 2″ mark and clip each pleat. Space the pleats one after the other and clip them to make the mask 4″ wide. Adjust the pleats accordingly. The pleats do not have to be perfect as long as the mask is 4 inches wide. This is VERY important because if the mask is too short, it won’t go under the chin in some cases, and if the mask is too long, it could leave too much of a gap on the side of the face. Do not change the number of pleats as the bottom pleat is especially important to the curvature of the mask under the chin. See image 2.

- Sew the pleats down by sewing 1/4″ seam. Repeat on the other side. When finished, the pleats will all be going down.

- Cut two pieces of yarn 36” long. Mark the center of the yarn and clip to the center of the mask where the pleats are. Mark the center of the 36” strip and place under the edge of the mask where the yarn is. You want it halfway under the edge. Fold the side of the fabric strip over the top and clip in place (this is the “binding”). Start sewing where the pleats are. As you sew you need to scoot the yarn into the fold of the tie/binding fabric. Use a 3/8” seam and stitch down the edge of the mask. Keep folding the fabric in half lengthwise and stitch all the way to the end. Flip it over and sew the 3/8” seam all the way to the other end of the strip. To reinforce, sew a second line of stitching on both sides of the mask where the pleats are. Repeat on the other side. Note: the medical fabric does not fray so a single fold is sufficient. See image 3.

Mask Prototype 2 Instructional Video

Mask Prototype 2 Instructions

Download a pdf of these instructions

This mask is made of 2 layers of HALYARD H600 medical fabric. It has a roundish shape and darts to snug the mask under the chin. There is no binding on this mask. The raw edges are topstitched after insertion of the nose wire and attachment of the ties.

The mask has passed the Respirator Fit Test. Please note that the masks will be sterilized after they are returned to the hospital.

Supplies

- Halyard H600 FABRIC supplied by the hospital.

- Cut 2 pieces 10” x 6.5”

- Cut 4 pieces 1” x 20” (these are for the ties)

- MASK TEMPLATE provided for a pattern

- Thick card stock or other material to make a firm template for tracing

- 100% ACRYLIC YARN, size medium #4

- Cut 4 pieces 20” (used for the ties)

- Note: We are testing materials to make this easier, but for now this is how we are doing it. The strength of the ties is critical to get a snug fit. (We have tested Double zig zag stitching without yarn and it does not work…)

- 16 GAUGE CRAFT WIRE for the nose wire.

- Cut 1 piece 5”. Make a loop at each end of the wire. All loops should face the same way. Press the loops flat with your pliers to make sure there are no sharp edges sticking up. (Loops are needed to keep the wire from poking through the fabric.)

- Note: If you don’t have 16-gauge wire, use 20-gauge wire, but cut 3 pieces, make a loop on all ends.

- TOOLS

- Sewing machine that can do a straight stitch and zig zag stitch. Your presser foot needs to be able to accommodate the zig zag stitch.

- Ruler

- Scissors

- Pins or clips

- Jewelry pliers that have tapered round ends and cutter or needle nose pliers and wire cutters

- Ink pen to trace the pattern onto the fabric

- EXTRA HELPFUL: cutting mat, long ruler and rotary cutter!

- MACHINE Setting: 2.5 stitch length or whatever the “normal” stitch is for your machine. The zigzag stitch setting used is 2.0 length and 7.0 for width. If your machine does not go to 7 for a width, use the widest setting.

Directions

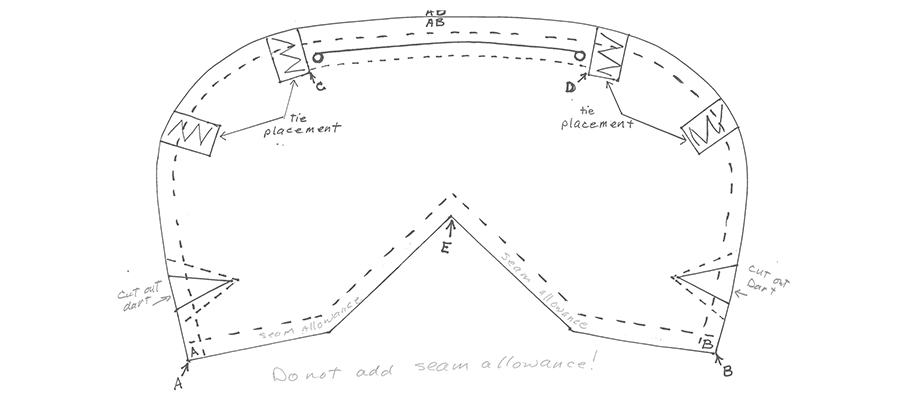

Step 1: Mask Template.

Print the template and glue to a thin cardboard such as a cereal box or card stock or use template plastic. The thin “cutting mats” are also good template material. Trace the pattern onto a 10” x 6.5” piece of fabric. Carefully cut it out. There are cutouts for the 2 darts. Cut out the darts on the solid line. DO NOT CUT OUT THE TIE PLACEMENT MARKINGS. Layer the 2 mask pieces and clip.

Step 2: Making the mask ties and attaching to the mask.

Take a piece of the 20” x 1” medical fabric and 2 pieces of yarn. You will be folding the fabric in half lengthwise, tucking the yarn into the fold and sewing with a 3/8” seam. As you sew, continue tucking the yarn into the fold until you reach the end. Repeat until you have 4 ties. (We like to sew at an angle across the end of the tie to secure the yarn. Do not worry about the first end as it will be sewn into the mask.)

Step 3: Set your machine for ZIGZAG stitch to attach the ties.

We used 2.0 for the stitch length and 7.0 for the stitch width. The darts should be cut out and you should have markings for placement of the ties.

Tip: Make a second template and only cut out the tie placement marks. Lay it on the blue side, making marks for easier placement of the ties.

Place the squared end of the tie 3/4” in from the edge, between the 2 layers at the notch, LOOK at the template to make sure you place it in the correct place. Hold together and place under the presser foot. Zigzag stitch from the outside edge of the mask to the end of the tie that’s between the layers; reverse stitch back to the starting point of the stitching. Carefully place and zigzag stitch each tie.

Step 4: Darts and partial topstitch of the mask.

Next, sew the darts. NOTE: SEW THE DARTS ON THE BLUE SIDE! The dart seams will show on the outside of the mask. Fold and sew each dart using a tapering seam from the narrow point of the dart to the bottom ending with 1/4” seam. Backstitch at the beginning and end.

When the darts are completed, sew a 1/4 topstitch from one corner of the mask around to the other corner folding the darts up toward the top as you sew. (Sew from point A through AB and to point B). The other seams are left until last so the nose wire can be inserted.

Step 5: Insert the wire.

Your prepared wire should be about 4.5” long. If it is longer, you may need to adjust it as it needs to fit between the ties sewn into the mask. Push it all the way up to the seam made when you topstitched the two layers together and used clips to hold it there. Now you will CAREFULLY sew a 3/8” topstitch from Point C to Point D between where the top 2 ties are sewn in. Position the presser foot so the right edge is on the line of the 1/4” topstitching so that you are encasing the nose wire within the 3/8” seam. You want to go slowly so you can control where the wire is. You don’t want a broken needle!

Note: If using 20-gauge wire, be sure to make that loop at each end of all wires and push and clip all 3 into position. All ends must have a loop: We don’t want to injure health care providers!

The wire is inserted between the top two ties. Stich a 3/8″ seam to encase the wire.

Step 6: Sew the outside seams.

You are going to sew on the blue side so that the seams will be on the outside of the mask. Slightly bend the nose wire so you can line up the remaining seams and clip, blue side out. Using a 1/4” seam, backstitch at the beginning (Point E), sew to 1/4” from the corner, turn the mask and sew to the end and backstitch. Trim the seam to 1/8” inch to trim it up a little.

Now you will sew a 1/4” topstitch on the outside edge from one dart across the seam you just made and across the other dart. You are done!

Disclaimer

The surgical mask information is provided as research information only and has not been tested for commercial use. The mask Information is provided with permission for the recipient to freely use, copy and modify without restriction, subject to an obligation on the recipient to recognize University of Florida Health (UF Health) as the source of the information and design depicted in this material. The design is bare bones and materials should be locally available at hospitals that sterilize equipment. This design is for an adult mask for anyone at a higher risk for coronavirus, exposure or concern thereof. The mask Information is experimental in nature and the safety or efficacy for use in humans has not been proven. It has been tested using the standard N95 fit test and can fit test pass most people. It should not be used without the wearer N95 fit testing before use. If reused it is advised to use one of the standard CDC N95 mask reuse protocols. The design, and masks built in accordance with the design, have not been approved by the FDA or NIOSH.

DISCLAIMER: THE MASK INFORMATION IS PROVIDED “AS-IS, WHERE-IS,” WITHOUT REPRESENTATIONS, CONDITIONS OR WARRANTIES OF ANY KIND, WHETHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, OR THAT THE USE OF THE MASK INFORMATION WILL NOT INFRINGE ANY PATENT, COPYRIGHT, TRADEMARK OR OTHER PROPRIETARY RIGHTS. THE RECIPIENT IS SOLELY RESPONSIBLE FOR DETERMINING THE APPROPRIATENESS OF USING, REPLICATING OR REDISTRIBUTING THE MASK INFORMATION AND DESIGN. IN THIS REGARD, THE RECIPIENT ASSUMES ALL LIABILITY FOR DAMAGES, OF WHATEVER NATURE AND DESCRIPTION, WHETHER IN CONTRACT OR IN TORT, WHICH MAY ARISE FROM THE USE OF THE MASK INFORMATION AND DESIGN. THE UNIVERSITY OF FLORIDA, INCLUDING ITS EMPLOYEES AND AGENTS, WILL NOT BE LIABLE TO THE RECIPIENT OR TO ANY THIRD PARTY FOR ANY LOSS, CLAIM OR DEMAND MADE BY THE RECIPIENT, OR ANY LOSS, CLAIM, DEMAND OR JUDGMENT AGAINST THE RECIPIENT BY ANY OTHER PARTY, DUE TO OR ARISING FROM THE USE OF THE MASK INFORMATION AND DESIGN BY THE RECIPIENT.